Ditch Witch truck-based vacuum excavator units

|

|

|

As well as selling and servicing Ditch Witch's range of robust vacuum excavator technology, the New Zealand arm of this globally recognised company will also build you a bespoke truck- or trailer-mounted unit to suit your requirements.

Vacuum (or hydro) excavation has increased in popularity hugely over the last couple of years. The familiar orange livery of Ditch Witch is leading the charge in this area, with technically advanced hardware options available for a variety of contractors.

When it comes to affixing the technology to trucks and trailers, Ditch Witch New Zealand offers a number of solutions, assembling truck-based vacuum excavator units for a large variety of private contractors and infrastructure maintenance entities.

Vacuum excavation allows contractors to work faster and smarter, digging beneath the surface in the manner of a mini excavator, but in a far cleaner, more compact manner. A two-metre wide hole becomes a neat and tidy opening instead.

The spoil from the excavated area is sucked up into a trailer- or truck-mounted tank, eliminating piles of dirt and debris taking up space on and being tracked through the work site – especially beneficial in environments with high traffic or pedestrian flows at their periphery. As a result, local councils and subsidiary stakeholders are requesting the use of this technology in ever greater numbers.

Ditch Witch vacuum excavators

"The system is essentially water blasting a hole and sucking away the spoils at the same time," says Ditch Witch New Zealand general manager John Grant.

"Our customers generally only need to utilise a vacuum excavation unit once and they see the benefits of this work method. It's especially good for Ditch Witch customers because we sell and service the hardware, as well as building the best bespoke solution for their business."

Grant says there's no set truck chassis size that works best over all others when it comes to assembling vacuum excavator units; it depends purely on expected work capacities, so 4x2, 6x4 and 8x4 axle configurations all provide for dependable bases to build on.

"The majority of trucks we're building on are second-hand units. Vacuum trucks don't tend to do high kilometres, so the majority of clients prefer to build on a vehicle that might be a few years old and no longer needed for frontline haulage or transporting duties."

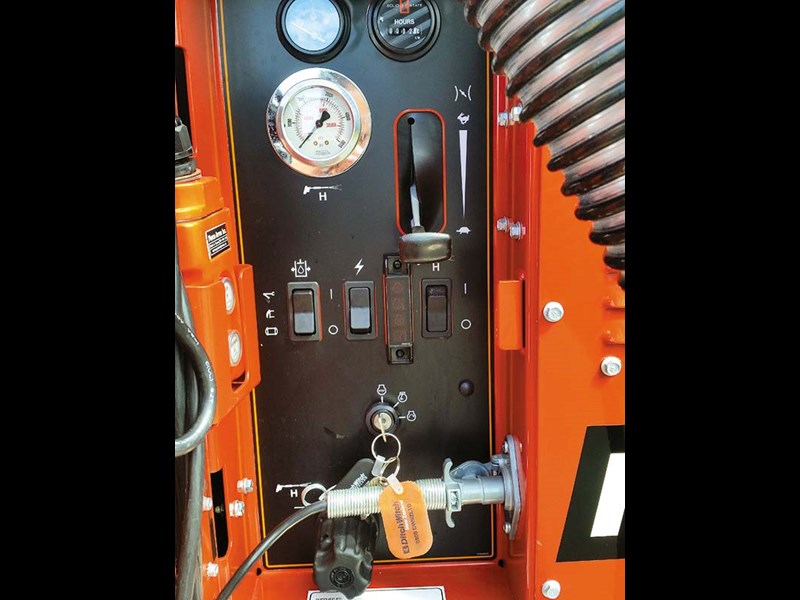

Ditch Witch's vacuum excavator power packs come in a variety of sizes, with trailer-mounted FX20 and two-axle truck-mounted FX30 units being at the smaller end of the scale. FX50 and FX60 power packs are generally suited to larger platforms operated by bigger contractors and councils. The number suffix for each model refers to the power pack's maximum horsepower.

Water tanks are available in 300 gallon (1136-litre) and 500 gallon (1893-litre) sizes. Twin tank set-ups are also becoming an increasingly common option; the idea being, the more water onboard, the less downtime required for refilling during the working week.

Ditch Witch on a truck

By working with a transport engineer who calculates overall weight and axle loading distribution, Ditch Witch New Zealand provides a finalised drawing for the customer on completion of the build.

Accurately assessing the expected weight of each vacuum excavator assembly is crucial and Grant and his team work very closely with their clients in order to make sure that, when full, the truck that the assembly is being fitted to will have the power needed for the task, and be legal for use on New Zealand roads.

"Depending on the material being sucked up into the spoils tank, weights can vary hugely. There can be a big difference between soil and sand for example," says Grant.

"It's not so much about the overall weight of the truck, but rather axle loading rates. Engineering a solution for perfect weight distribution is key, because there are so many variables to take into account; an average 500 gallon water tank weighs 300kg empty, but almost 2.5 tonne full.

"Add to that a spoils tank that could carry a maximum weight of eight ton and you have the potential to add a lot to your overall weight."

When blueprinting vacuum excavator trucks, Ditch Witch calculates spoils weight at 1.75kg per litre; a generic calculation used for consistency.

"If there is one trend that is developing, it's that vac units are getting bigger overall," says Grant.

"While we continue to build what we term 'contractor grade' units that can be as compact as a trailered FX20, these days the size of the power packs and spoils tanks chosen is predominantly at the top end of the Ditch Witch range.

"All the individual parts of the unit – the power pack, water tank and spoils tank – arrive here palletised. We then take delivery of the truck from the client and begin standard skid frame assembly in order to fit each of the main components. In all, the average build time for a vacuum truck at our Auckland depot is between four and six weeks.

"We're confident this part of our operation is going to grow in the months ahead. The units we're building are being shipped all over New Zealand and I can see the potential for larger numbers of customers utilising this technology in the near future."

For more awesome features like this one, subscribe to Deals on Wheels magazine.

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.