Product feature: Steelwrist tiltrotators

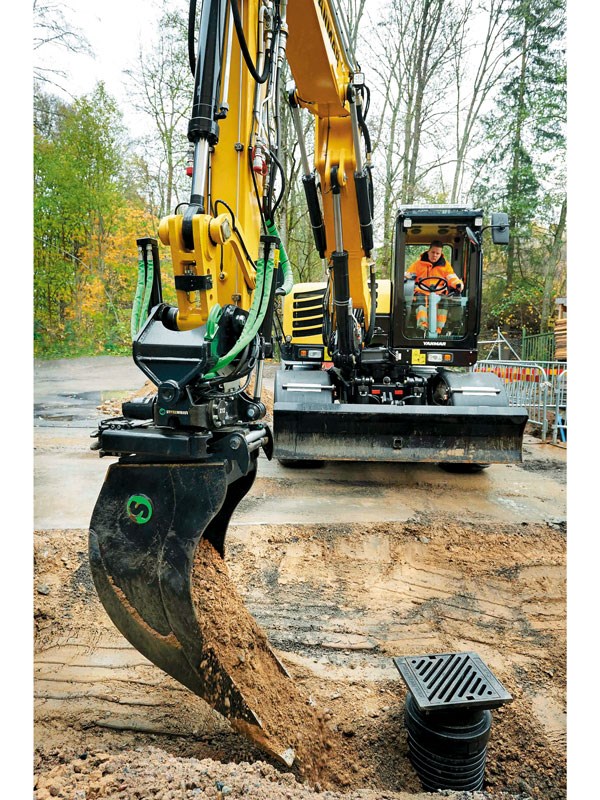

The Steelwrist tiltrotator transforms the excavator into a multi-tool, which can perform many operations, increasing productivity

|

|

45-degree tilt angle for greater flexibility; no unnecessary machine shuffling

|

With labour costs on the rise, contractors are looking for other methods to make the most out of their crews. One tool proving effective for early adopters is the Steelwrist tiltrotator.

The tiltrotator functions as a wrist between the arm of the excavator and bucket or any other tool connected to the quick coupler. It does exactly what its name describes by allowing users to not only tilt an attachment left and right, plus/minus 45 degrees, but it also rotates 360 degrees on 2.5- to 40-tonne excavators.

Efficiency can be increased even further by opting for an automatic quick coupler system, says Synergy Positioning Systems Ltd, the New Zealand Steelwrist distributors.

What the users say

|

|

Grading bucket makes finishing work a breeze

|

Audet Enterprises "Tiltrotators transform the excavator into a multi-tool, which can perform many operations, increasing productivity upwards of 40 to 50% in some applications," says Jake Audet of Audet Enterprises.

"The ability to rotate and tilt eliminates the need to position or reposition the excavator. Being able to rotate the bucket allows the operator to work closer in tight areas, place and position aggregate or stone with increased accuracy, backfill at lightning speed and contour, or sculpt the area," he says.

Jake says he mainly uses his tiltrotator, fitted to a Caterpillar 304E, for tasks such as digging foundations, backfilling small foundations, shaping berms, and digging trenches.

He says it’s more of a question of what can’t a tiltrotator do? The versatility of the attachment to do almost anything helps free up Jake’s crew from hand digging tasks. "I run two-man crews now," says Jake.

"I don’t need a third guy with them. I can have one guy running the machine and a ground guy, but (he’s) not really even helping him. It’s all seamless." "Once you use one, you kind of want everyone to have one," Jake says. "Why wouldn’t you want to be more efficient? The whole point is to help everyone."

Innovative Lawn & Landscape

|

|

The Cable bucket is ideal for confined spaces

|

Similar to Jake who also runs a Caterpillar 304E, James Doyle, owner/operator of Innovative Lawn & Landscape went with a Steelwrist X04 tiltrotator, saying the build quality and customer service stood out to him compared to the other suppliers.

"As far as customer service goes, they’re very down to earth and very easy to talk to," James says. "There’s definitely a personal connection, which made me a lot more comfortable choosing Steelwrist. Price wasn’t really a factor there, to be honest; I look at who’s going to be there when something breaks."

James’ jobs typically consist of drainage work, hardscaping sites, and other landscape construction projects. He frequently uses the Steelwrist tiltrotator for tree work, using a grapple to feed the tree through the chipper, which makes tree removal much safer.

"It eliminates a lot of the hand work, and it actually makes it a little bit safer," James says. "Guys aren’t standing right at the mouth of the chipper anymore. We’re able to just take a full tree and throw it right through the chipper."

James says there’s no loss now when scooping material out of a tip truck and backfilling trenches can be done with ease. He’s also able to dig left and right while sitting in one position.

"It eliminates me having to have a guy there with a rake or a shovel to move that material away from, say, a wall or another structure," James says. "I can completely do everything from one spot. It leaves us with minimal site damage because we’re keeping the machine in one place."

The efficiencies add up over time and can result in getting jobs done quicker, allowing crews to focus on other tasks. "On 90% of our jobs, it cuts out having an extra guy stand there with a shovel or a rake," James says. "That guy could be running and grabbing materials, for instance.

"Tiltrotators are also well suited for tight areas where the machine isn’t level. It doesn’t matter if the excavator is leaning, the tiltrotator holds the attachment at the angle you desire."

Price versus productivity

|

|

Gripper is an essential accessory for fencing and forestry work

|

A new tiltrotator is a premium investment, but both Jake and James say it’s well worth it. They agree that the attachment quickly pays for itself, thanks to the productivity it provides.

"It’s a little shocking, but once you swallow the pill of how much it costs, the amount of money that it’s saved me in the long run means it has paid for itself in a year," Jake says.

"There are jobs I wouldn’t even be able to do if I didn’t have it. I also can be aggressively bidding things knowing that I can do a job when other people think it’s going to take them forever, but for me, it’s going to take a couple of hours."

|

|

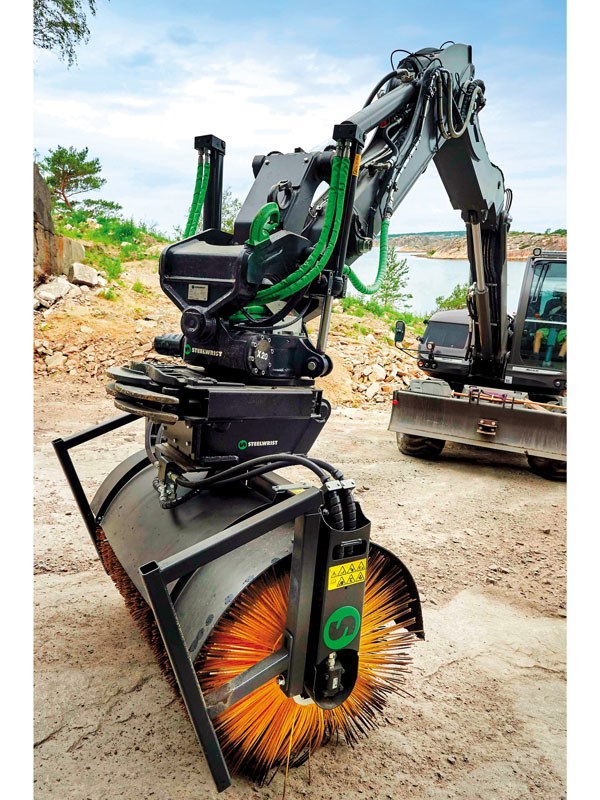

Sweeper is handy for big paving works or even snow removal

|

Base list price for a Steelwrist tiltrotator for a compact excavator can range anywhere from $30,000 to $50,000 with options such as the gripper extra, says Synergy. James, who spent around $50,000 for his tiltrotator package, advises other landscapers interested in a tiltrotator to buy it through a dealer and have it installed on a new machine as a package deal to be as effective and efficient as possible.

"It was kind of a no-brainer to me if we were buying it new to just not really worry about the price tag, to just work it every single day," James says. "So, the price tag really wasn’t a huge concern for me. It was at first, but then I realised I have to work this thing a day and a half a month to make the payment."

Get a demo

|

|

With pallet forks, tiltrotators are a versatile warehouse tool

|

For those curious about a Steelwrist tiltrotator, James advises getting a demo. "As soon as you demo one, you’re not going to turn back," he says. "You’re going to want one, and you will find a way to do it—at least if you’re in to win it like me. Once you use it, you’ll realise the nature of it (tiltrotator) and how efficient you can be."

Jake adds, "I truly believe everyone should have one. I mean, it’s kind of silly not to. If someone’s saying there’s an efficient way of doing this and it’s going to cut down your time, you’re going to spend some money, but you’ll be able to do more work and make more money, why wouldn’t you do that? "Look at this way: tiltrotators don’t cost money, they make money."

Steelwrist tiltrotators

Tiltrotators are well-established in European markets, with more than 90% of all excavators in Sweden between three and 30 tonnes equipped with a tiltrotator, the manufacturer says.

Synergy says they can supply a complete product offering for modern excavators. All sizes have Front Pin Lock technology. The tiltrotators have a low build height, high tilt angle, and an unbeatable relationship between strength and weight, thanks to steel casted components, says the distributor.

Features in a glance

- One of the most compact and optimised tiltrotators on the market

- 45-degree tilt angle for greater flexibility

- Front Pin Lock as standard

For more information, contact Jason Stamp on 0800 587 054 or visit synergyequipment.co.nz.

Find new and used heavy machinery for sale in NZ

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)