Review: SharpGrade Leveller

|

|

|

|

|

|

Followers of Kiwi innovator Rodney Sharp will not be surprised that the release of his latest piece of machinery, the SharpGrade leveller, has stepped up the game once again.

Strange as this may seem to some manufacturers, the first step to producing the SharpGrade leveller involved Sharp and his team at Progressive Equipment Ltd, talking to end users of levelling machinery to find out what they 'actually' required from a piece of kit.

This gave them a base to work from and meant the end design would produce the desired outcome as required from the product — or as we would say, 'making sure the machine does the job right'.

What exactly is a leveller?

Levellers, in one form or another, have been used overseas for many years, but have only began to show themselves in numbers fairly recently here in New Zealand.

Similar to all levellers, the SharpGrade leveller is essentially an independent blade (called a mouldboard) fitted to a skid steer, with an extra set of front wheels to stabilise the blade. In the case of the SharpGrade, it can also be easily adapted to fit to an excavator.

The advantage with levellers is they can cut, grade, or spread product to very fine tolerances over wide areas, and they really come into their own on sandy areas.

So, is it like a grader?

If you're comparing machinery, then yes, they do have similar features and operate in a similar way. In the case of a grader, its uses are fairly limited, especially when it comes to smaller sites, and there are a wide number of skills to master for a grader operator to become truly proficient, even with the modern technology available. Also, for employers, the problem of finding an experienced grader operator that doesn't know their true worth is pretty much a thing of the past.

What can a leveller do?

A leveller's talents can be turned to a number of tasks, such as prepping roads and car parks, cutting sites, landscaping work, the range is large. Also, being an attachment means the leveller can be swapped out for something else, adding to the versatility that contractors require in this day and age.

What is special about the SharpGrade leveller?

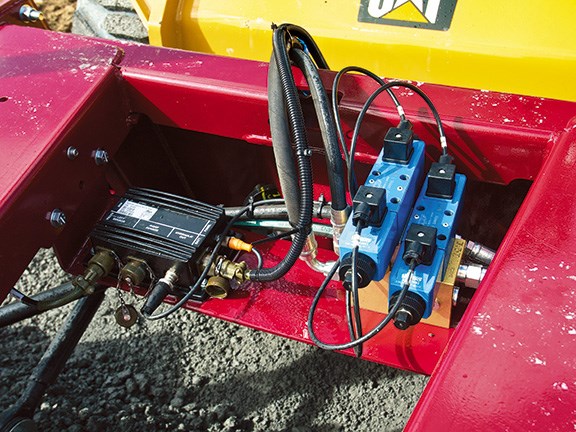

Well, thanks to the technologically innovative Rodney Sharp and his team, the leveller design that most brands are known for, has had something of a makeover, resulting in Progressive Equipment's SharpGrade model. Coupled with some clever technology, the scope has been blown wide open for operators to achieve even more professional results faster.

Some of the innovations

"Things started off really simple," says Sharp. "Operators told us it was difficult to see the blade, so we fitted two mirrors." Not so simple was the matter of keeping the blade stable to ensure that fine tolerances achieved when a machine is new were still there as the machine got a few thousand hours on the clock. This was very cleverly overcome with the placement of truck-style torque rods and replaceable rubber bushes designed to remove any flexing.

Probably one of the most important innovations is the design of the mouldboard, which rolls the cut product forward, meaning nothing is lost over the top of the mouldboard (blade), and the skid steer can keep the correct contour.

Also, simultaneously the cut product is shaped by rear of the mouldboard which gives a top finish. It has not been forgotten that the SharpGrade leveller needs to be lifted onto the back of a truck sometimes, so strategic lifting points are positioned to make this task safe and easy.

The test

It's all very well jumping in the operator's seat and running a machine for a while, but sometimes it's even better to get the opinion of someone who is seriously considering forking out cold, hard cash for one. In our case, today was our lucky day as contracts civil manager Arne Stanners, from Euroclass Design and Build Ltd, was on hand to jump into the hot seat and give the SharpGrade leveller a run.

In the case of the test run, some roading at a new subdivision in South Auckland looked to be the ideal place to try out the leveller. Euroclass was looking at a complete package, which consisted of a brand new Cat 272D skid steer (as featured in last month's issue, DOW 250), and a Leica machine control system.

With some serious money riding on his shoulders, Stanners climbed into the seat of the Cat 272D and proceeded to do a number of runs. After an hour or so behind the controls, he reported back that the machine setup had more than met his expectations, saying it was straightforward to operate, with vision ahead being clear.

"I can easily see how this could fit into our operation. In this configuration, a semi-experienced operator should be able to produce the quality finish that we require, and it should negate the need for a lot of hand finishing."

Stanners gives a good example of why the SharpGrade leveller should suit their business. "Our company does a large variety of commercial and domestic construction work. We have an older grader, but it sits around quite a lot. If we had a leveller such as the SharpGrade, then we wouldn't need the grader and we could easily swap out the leveller with a bucket or other attachment if the skid steer was required to do something else."

Once again, Kiwi innovation has come to the fore with the SharpGrade leveller. For businesses looking for equipment versatility without compromising the quality of the finish, this piece of machinery could be just the ticket.

Check out this video of the SharpGrade Leveller in action.

Never miss an issue. Subscribe to Deals on Wheels magazine here.

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.