Forestry: Are loggers getting the right food?

Are forestry workers compromising their safety by eating too many pies and energy drinks? And should they have more breaks? Patrick Cox takes a look at worker safety in the forestry industry and wonders whether logging companies are doing enough.

We will forever be looking for solutions to the hugely-problematic accident rate across all industries — it's on the lips of all you talk to, especially forestry, because of the high media profile it is receiving.

On one of my daily exercise walks the other day, I crossed paths with a forestry trainer at the polytechnic. I listened with interest to his point of view and he made the bold statement, "We will never fix the problem." Why? Because we are raising our children without built-in danger awareness.

You know, he's right. The children of today are so protected by the laws of society and they have no idea about danger at all — no smacking, no riding your bike to school, no bull-rush. At school today, punishment is no more than a slap with a wet bus ticket. The bubble-wrapped society we have created is killing our people.

The issue of fatigue at the felling face was raised with a logging contractor — by late afternoon are the crosscutters getting tired and running out of steam? Does this make them more prone to making mistakes? Statistically this question could be easily answered and if this was the case, then it could be addressed. So this leads to another question: are bushman getting the right breaks? Nothing runs on an empty tank, even your car coughs, shudders, shakes and stops when running out of gas.

Changing times, changing eating habits...

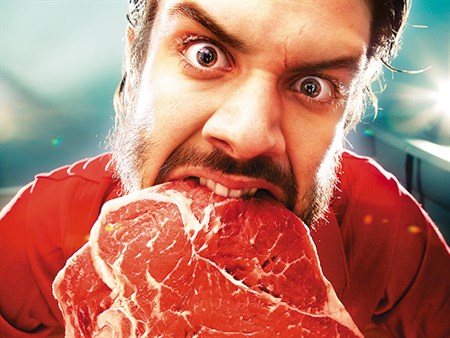

A logger's day normally starts on the job at 7am. What did they eat for breakfast? Was it a quick stop at the tuck shop for pies and fizzy or energy drink, wolfed down in the back of the gang bus on the way to work? Is this good nutritional tucker? Hell no. The most important start to the day is breakfast, as it gets the metabolism going.

What breaks do the logging crews have today? In the past, the first break was at 10am with a big cook-up — steak and eggs, bacon and eggs, chops and eggs and onions. Whatever they brought to work was cooked up on that first break. Good solid food with a cup of tea or coffee. Then the second break was at 1pm, with probably just a sandwich, biscuit, tea or coffee or juice — the pattern here is to keep the bushman's tank full. If you don't, then the same thing happens. He runs out of gas and, like the car, he shakes, rattles, and rolls to a halt.

Once a logger's tank is empty, he needs a break to allow it to refill, you just can't keep working and fill the tank at the same time.

With the economic climate changing, a lot of logging crews opted for one break in the middle of the day — no more cook-ups. Was this the catalyst for the increase in deaths? Some crews do not even get together at smoko time now, instead just sitting in their respective machine on their own and eating their boring sandwiches with their cuppa tea. This doesn't develop crew culture and it prevents discussion on events in the past break. It's just a tailboard meeting in the morning before you start now, as I understand it.

Forestry fatigue and safety

This subject has continued to intrigue me over the last few weeks and I've raised the subject with a couple of logging contractors, just to be surprised by one response to this problem and the in-depth thought he has put into resolving the issue. I suggested to him that the breaks his operators were having could be hazardous to their health and for the next ten minutes I sat and listened intently to his solution. By the time he finished talking, I was converted to the way he had overcome the problem of fatigue.

This contractor has been double-shifting one machine, two eight-hour shifts with the right designated breaks in between. What he found after that first half-hour break, which often turned into forty-five minutes, was that the operators would go back to work but their rhythm had been broken and they took a while to come back up to speed — hence important production was lost. Re-evaluating (and I guess this was a little trial and error), he reduced the shift to six hours with no specified breaks — the operator would simply grab a cup of tea and sandwich while walking to the next tree. At the end of the six-hour shift, the next operator would be on the job and the two operators would work together to grease the machine and discuss any issues. The second shift was exactly the same. Now, here's the interesting part: production stayed exactly the same and the operators got their normal pay as if they had completed eight hours.

The forest company still got its tonnage, the benefits to the contractor were less machine hours, less fuel burn, and safe and happy employees — it's a win-win for all involved.

The second company I spoke to is not in forestry, but employs approximately one hundred and twenty people in hard labouring work similar to the level required in forestry.

They have put a lot of thought into this, they employ the unemployable and turn them into a skilled work force, through training, attitude, and showing that they care. There are rules, and if you break them, you're pretty much gone. If a crew is staying in another territory, they house and feed them — providing food and drink every day for workers to help themselves when hungry. Some of these people eat as if there will be nothing tomorrow, perhaps related to the environment they grew up in. The company would remind them there would be more food again the next night.

What I like is its policy on safety and caring for its staff — at the end of every day the workers have to fill in a form on what sort of day they've had. They fill in hazards they came across, note training that they might need, and, most importantly, are reminded to not be afraid to tell their mate if he's doing something dangerous, because they want everyone to go home each night.

The workers practice 'what if…' scenarios — what if I do that? Will it cause an accident? Referring back to the form, they tick a box regarding what sort of day they've had — OK, good, very good, and so on. These are analysed every morning by the managing director. If there are a number of OKs, there is a problem (OK being at the bottom of the scale), so their system kicks in and they can deal with it quickly.

Keep them machines running

This is just a brief overview of a couple of very intelligent companies which have put a lot of thought into keeping their teams safe — and when you look deep into it, a couple of cans of V energy drink and a meat pie will not keep your team safe and productive all day. Machines are manmade, so of course break down and need repairing — and if it does break down, the contractor is hell bent on getting it back to work as quickly as possible. Loggers break down as well, but do we care enough to look after them?

For the latest news, reviews and articles, subscribe to Deals On Wheels magazine here.

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.

.jpg)

.jpg)