Restoration Project: FGK Morris—Part 29

With the 30-part deadline looming, the pressure is on to piece the last few parts together

There have been two jobs that have been causing particular pain: getting the quarterlight window rubbers sorted and finishing off the paintwork with the final bit of green around the bottom skirt.

|

|

Only a bit of green to go and we’re all done

|

Although we have the quarterlight glass sorted, we actually have six sets at our disposal when the contents from three trucks in stock and numerous donations from around the country are taken into account.

The problem appears to be with the window rubbers, as Jeremy Tagg from Bespoke Auto Glass has been looking everywhere (including England) for the correct configuration of rubber to fit the opening portion of the glass.

The upshot of all this is that it’s looking increasingly as though we’ll have to settle

for windows that don’t open, at least in the short term.

As for the problem with the green paint, it’s not so much to do with the paint itself but with the dork who’s doing the job—yours truly that is.

As explained in a previous issue, the wings were in a diabolical state, as the truck appears to have been moved around in a past life by shunting it with a front-end loader or something similar. This made for a difficult repair job even for a panel beater who’s had around 45 years in the game.

While the panel beater who did the job says he could have made them look a lot better if he’d have had the time and I had the money, with neither being the case, we both had to settle on a happy medium by leaving me with the task of putting the finishing touches to the job—not a good idea in hindsight.

It’s one of my regrets that I didn’t spend some extra money on the panel work in the first instance, as I now have one hell of a job to make them anywhere near good enough to get a semi-decent finish before the final coat of paint goes on.

But having already fitted the wings to the cab, aside from the fact that we’re seriously running out of time, we need to crack on and make the best of what we have, and there’s plenty to be done that’s for sure.

A bit of mechanical stuff

|

|

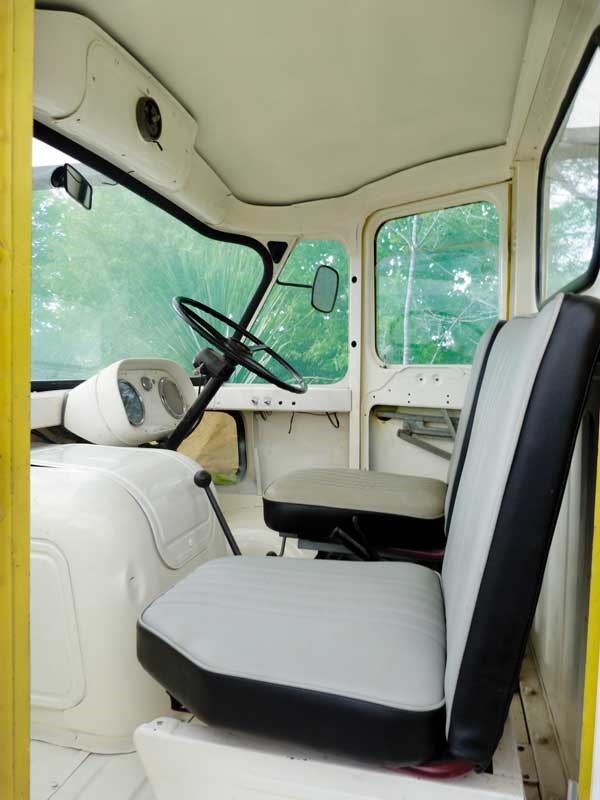

Driver’s perspective

|

Something you don’t really think about when you’re carrying out a long-term restoration is that by the time you’ve reached the end of the job (in this case two-and-a-half years), the work you did first has by this time been sitting around all that time waiting for the rest of the job to be completed.

This was the case with stuff such as the brakes and all those final adjustments that you think you’ll get around to when it actually needs to be done.

Well, that time has now come and a close inspection revealed that the entire braking system was temporarily held together with nuts and bolts that either need split pins to be fitted (or locking nuts) and clevis pins to be put in place.

A recent count of the linkages that connect the handbrake lever to the weird bisector cylinders that operate the rear brakes came in at around 15 separate points at which to adjust the system.

Fortunately, the truck has been given a drive around my mate Murray’s old orchard to keep things working from time to time. As the old saying goes, ‘use it or lose it’.

As an aside, that was an issue we had some years ago when I was part of a volunteer team at an Auckland transport museum. We just couldn’t get management and museum purists to understand that motor vehicles are unlike a lot of other museum artefacts, in that they need to be used in order to be kept alive.

It is for that very reason that right at this moment in time, there is a huge resource of vehicles from a bygone era sitting in a warehouse somewhere in South Auckland that the general public doesn’t get to see anymore.

|

|

Passenger’s perspective

|

Rant over, because if the public is ever going to get to see my recreation of a bygone era anytime soon, there’s still a lot to be done, even though they’re just a lot of little jobs, such as finishing off the bumper and fitting it and manufacturing some long-awaited steps to make entry and exit from the cab a lot easier.

A small apology to the readers. I know that progress may appear to have been painfully slow over the last couple of months, something I can put down to the problems I’ve been having with getting those confounded wings looking right.

Having now accepted the fact that they’re never going to look perfect, we’re now moving on with the completion of the interior of the cab, with only a few small features needed to finish off that part of the job. While at first, the business of getting the brakes working properly looked like a major undertaking, it, in fact, turned out to be dead easy.

I say ‘dead easy’ with a little bit of tongue in cheek, as the tests we’ve carried out to date have been to drive the truck up to a speed of about 20km/h and apply the brakes on a loose gravel track.

While this proved to us that all the brakes will lock up evenly and leave equally-proportioned skid marks on the gravel, the machine at the testing station could produce a different set of statistics, and while I don’t think this will be the case, we’re simply going to have to wait and see.

As previously described, it looks as though the job of getting the handbrake up to an acceptable operating level is going to be an entirely different kettle of fish—a job for next month’s issue.

With the deadline of the completion of the job coming down upon us, there’s still much to do, including some behind-the-scenes work of gathering together all the required information that’ll be needed by the authorities to get the truck legally on the road. But I reckon I’d better get cracking and get the rest of the real work done or I’ll still be writing about this experience in six month’s time.

Tip of the month

Set yourself reasonably obtainable targets

Coming up...

Can we really get this job done over a 30-month period?

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.

.jpg)

.jpg)

.jpg)