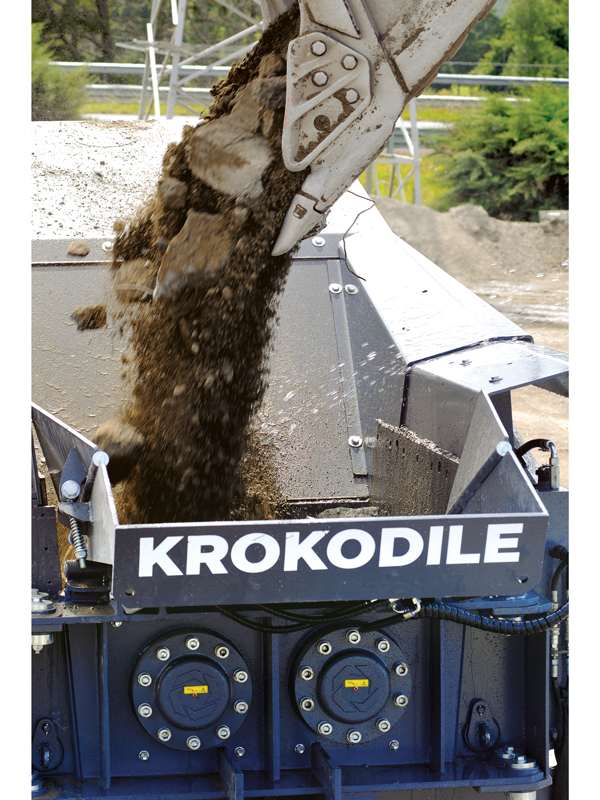

Product profile: Komplet Krokodile

Sanland Equipment Ltd held a demonstration session of the Komplet Krokodile slow-speed shredder for some key players in the Auckland concrete recycling industry

|

|

The Komplet Krokodile weighs in at 15T

|

Those entering Auckland from the south will be aware of the large aggregate recycling yard that sits alongside the Southern Motorway, not far from the Drury off ramps.

It’s here that Vernon Developments Ltd processes some 50,000 tonnes per month of crushed aggregates and bitumen for a large and active customer base.

Although, Cam and Becky Vernon’s yard and equipment list is impressive, on the day of our visit, the topic of conversation is firmly on the Komplet Krokodile slow-speed shredder being demonstrated in a far corner of the sprawling complex.

Shred, don’t crush

The Italian-made unit is specifically designed to shred a wide manner of products, from concrete, bricks, aggregates, and — with a change to a different set of shredding drums — tyres, wood, plastic, mattresses, and other household waste.

Although the Komplet Krokodile is a multi-function machine, its real strength lies in concrete recycling. The method it uses to produce shredded aggregate has been around for a while, and the end product is no different to one that has been crushed.

Powered by a 220hp (160kW) Volvo Penta diesel engine, the 15,000kg machine consists of two large hydraulically powered shredding drums that rotate towards each other and shred the raw material into a usable product for end use and easier compaction.

|

|

Two large slow-speed shredder shafts quickly handle the raw material

|

It can easily handle damp or contaminated materials and is an efficient way of dealing with materials that are not suitable for jaw or impact crushers. Additionally, the machine can be safely used by a careful operator who has relatively low crushing experience.

|

|

The machine can be easily operated by one person

|

"Controlled by a PLC (programmable logic controller) and full function remote control ensures it’s an easily operated machine," says Sanland Equipment sales executive Andrew Tomkins.

|

|

Andrew Tomkins

|

Incoming waste

Dealing with the incoming waste are sets of curved teeth positioned strategically on two big shredding shafts, powered by Danfoss Motors and large Brevini gearboxes.

"The Krokodile has two shafts that can be programmed to go in synchronous or asynchronous motion and can be set to rotate backwards and forwards in user-determined ways to give the optimal output for its current application," says Andrew.

"If anything uncrushable goes through it, the hydraulic fluid pressures peak and it backs off and goes again, until either the product passes or it gets thrown out without causing any damage to the machine."

Magnetic separator

After exiting the shredding chamber, a magnetic separator conveyor will catch the rebar and any other ferrous metal (containing iron) as it makes it way up the stockpiling conveyor.

|

|

The magnetic separator is hydraulically adjustable by a remote

|

One clever advantage not seen on many other brands is that the magnetic separator can be hydraulically adjusted by around 400mm and is fully controlled by the cordless remote control.

|

|

The multi-function remote control

|

"Because the shafts deflect the steel, it’s bent well before it gets close to the belt, so doesn’t pierce it and gets thrown out in small 300mm sections out of the side," says Andrew.

Rear hopper tilt

Another feature of the Komplet Krokodile is the tilt action of the rear hopper, something that allows controlled feeding of raw material and is no doubt helpful when repositioning awkward pieces.

It also highlights that a huge advantage of the machine is its ability to deal with irregularly shaped material. Not everything needs to be sized down to fit within a standard jaw or impact chamber, considerably reducing pulverising hours.

"To facilitate the larger pieces of concrete going through, you can rest them on the back of the hopper, which can hydraulically tilt, and it can push the material onto the slow-speed shafts," says Andrew.

"Movement in the hopper functions and also the magnetic separator is facilitated by a remote control similar to what’s seen on crane trucks and other remote-controlled crushers."

Transportation to site

The Krokodile tips the scales at around 15 tonnes and with a footprint that will take up a fraction of the space of some other crushers, should see the machine get comfortably tucked away in a corner when out on demolition jobs.

"The machine is very movable and tilts all the way down, so is a secure load on a transporter," says Andrew.

|

|

The machine tilts down for transporting and can be loaded on a suitable-sized hook bin truck

|

"There’s also a hook, suitable for a hook lift, so for an operator who uses bin trucks in demolition or waste processing can pick it up with a hook lift truck and take it where it needs to go."

A second set of shafts

|

|

A second set of shafts for wood, tyres, and other waste is supplied

|

The Komplet Krokodile is supplied with a second set of shafts that have sharper ends on them and are used for shredding wood, mattresses, tyres, and other types of waste.

"Swapping the aggregate shafts for waste ones involves about a two-hour change and eight bolts, along with an excavator or crane truck to move them in and out," says Andrew.

"The Krokodile has shafts that can be refurbished — it doesn’t have wear parts. You re-hardface the concrete shafts when required, and after a period of years on the wood shafts, you might tungsten carbide the edges. Apart from that, there are no wear parts within the shredder apart from the rollers on the conveyor.

The Krokodile is ideally suited to a business that wants to divert material from landfill and with the rates of landfill disposal now, the machine should pay itself off quickly.

"If you consider the machine can do over 100 tonnes per hour on concrete and the tipping cost of that 100 tonnes and then work that back to a payback for this machine, you’ll find it doesn’t take that long to add up," says Andrew.

"This machine is ready to take on the industry."

For more information, visit sleq.co.nz.

Find new and used heavy machinery for sale in NZ

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.

.jpg)

.jpg)

.jpg)

.jpg)

-(1).png)