Comment: Chain Placers—have you heard of them yet?

Forest Growers Research has had a project going for two years around automated Chain Throwers as a solution to reducing the incidents of injury to truck drivers on skid sites

|

|

The Primary Growth Partnership project between industry, research, and Government is titled ‘Te Mahi Ngahere i te Ao Hurihuri – Forestry Work in the Modern Age’

|

The way of the world is to mechanise tasks usually undertaken by people, especially when there are risks involved in that task or the task means there is the chance of long-term stress and damage to the person.

If you look at the definition of mechanisation, it is the use of machines, either wholly or in part, to replace human or animal labour. Stepping back, mechanisation began with human-operated machines to replace the handwork of craftspeople and today computers are frequently used to control mechanised processes.

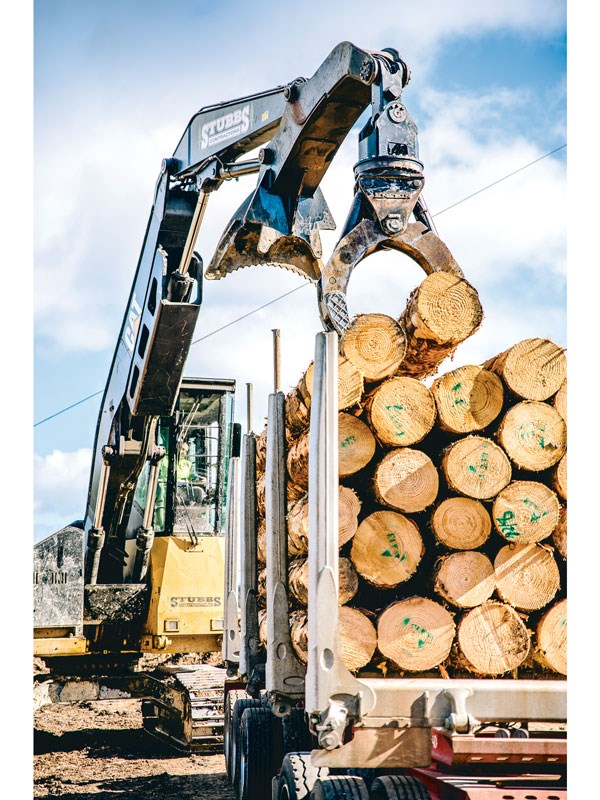

Forest Growers Research has had a project going for two years around automated Chain Throwers, as a solution to reducing the incidents of injury to truck drivers on skid sites. It is a Primary Growth Partnership project between industry, research and government and is titled ‘Te Mahi Ngahere i te Ao Hurihuri – Forestry Work in the Modern Age’.

The agreed objectives include:

- To find, or develop, an automated log truck load securing system suitable for debarked and slippery logs

- This system includes mechanisms to enable manual chain throwing to be eliminated and manual chain tensioning to be eliminated

- Required load restraint tension to be maintained automatically throughout the trip

- In-cab monitoring of load restraint status to alert the driver of any issues

There has been significant information shared with industry about the work around the Chain Placers, a new terminology for this task.

However, as expected after much consultation there are still some questions left to answer and a significant cost to changing over to this system for the log truck companies, who are already under pressure with the cost of Covid, fuel and a limited workforce.

At the most recent presentation there were some key questions asked about this research, for example: at the other end of the journey can the new Chain Placer retrieve the chains back off the load?

|

|

The project includes a range of commercially available solutions

|

The response was no, as there is no way to connect the chain at the winch side back to the Chain Placer. The vision of this project includes a range of commercially available solutions, with no single industry-endorsed system, but instead having options available.

It will mean that the load securing standards will be reviewed, alongside industry compliance with performance standards. It’s a project that clearly will drive further innovation and improvements in efficiency, load security, safety and wellbeing of drivers and operators over time.

|

|

There may be a significant cost to changing over to the system

|

The total project cost is $1.27 million, now budgeting for 2022/23 financial year. Are we sure we will have exhausted all options of improving the chain slinging techniques of truck drivers and further questioning asked, if there was validity in looking at other ways such as, the design of the landings?

Referencing the NZFOA Road Engineering Manual on landing construction, poor landing location, design and management can have major consequences for safety, the environment, production, and quality and value recovery.

A list of considerations is quoted in the manual and part of it covers loading out location and truck access – whether it be roadside landing, drive through landing, spur road end landing, or split level landing.

WorkSafe through the ACOP of 2021, requires that all landings shall be planned and constructed to allow for safe operations and included is load out areas, as part of an extensive list of requirements.

We often talk about low hanging fruit and according to the log truck drivers an easy solution would be to have a bund wall just off to the side of the skid, so they can be at trailer height to effectively throw chains over without excessive reaching.

This seems to be an obvious solution that could be created by maximising the existing process of the skid planning, which was going to happen anyway.

Finding a solution at the multiple load out points might be a more realistic solution rather than having to put a solution on every vehicle. A conversation with the loader driver could be another approach around how they can support the log loading and securing system and create more consistency without the complication of costs and variable manufacturing specifications.

They are there with equipment that can lift chains and minimise truck drivers’ risk and incidence. Further into the history of mechanisation, we remind ourselves of the Industrial Revolution, which was the transition to new manufacturing processes in Great Britain, Europe and the United States in the period from about 1760 to sometime between 1820 and 1840.

This transition included going from hand production methods to machines and the increasing use of steam power and water power in the development of machines and factory systems.

The Industrial Revolution marked a major turning point in history; almost every aspect of daily life was influenced in some way. In particular, average income and population began to exhibit unprecedented and sustained growth.

So, is the real issue that we have, ascertaining the real outcomes when driving the move from man to machine and the outlying effects that we do not seem to be able to predict until that change is made? With anything like the Industrial Revolution it’s hard to get a real handle on the pros and cons and the longevity of change.

Find new and used heavy machinery for sale in NZ

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)