First look: new Caterpillar 555 D-Series skidder

|

|

|

|

|

|

|

|

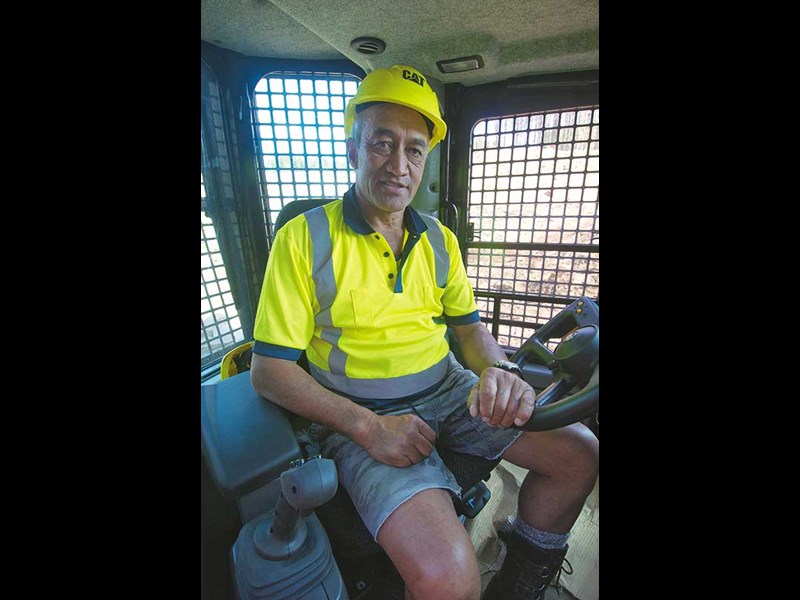

A forestry block tucked in behind the Kinleith Mill near Tokoroa, was the place that Gough Cat chose to unveil to guests the latest (and largest to date) Caterpillar 555 D-Series skidder. The Ed went along for a look.

I would say that Caterpillar designers must have a harder task than many in the same career path. Such is the dedication that Cat owners and operators have for their brand, it would surely mean banishment to the far side of the planet if a design team under-delivered on a Caterpillar product. We had turned up to see if the new Cat 555D was going to live up to the expectations of North Island forestry contractors.

The A&G Sinton harvesting site was an ideal choice for the event, with nothing but Cat gear operating as far as the eye could see. The open day followed on from a similar South Island demonstration held earlier in the week near Dunedin.

Judging by the branded apparel, Cat owners and operators made up the majority of guests, along with some owners of other brands who had come along to check out the competition.

The machine

Carrying a price tag that is probably in a direct ratio to its wow factor, the Caterpillar 555D weighs in at close to 21.5 tonnes. It is also the largest skidder produced by the company to date. With a wheelbase of 4083mm, it is 431mm longer and around 1015kg heavier, than the Cat 525D that A&G Sinton is operating on the site.

Power-wise, the new model runs a turbocharged six-cylinder C7.1 ACERT engine that has a gross output of 205kW (275 horsepower).

While all that grunt also helps the grapple carry a 2.04m2 capacity and have a retracted lift height of 3005mm, it is the engineering work under the engine cowling that has provided some serious design changes.

First off, safety has been addressed, with the repositioning of the radiator to the rear of the engine compartment. The benefits of this are immediately obvious, as it reduces damage from errant branches and logs, along with providing cleaner air to the system. This positioning also means less debris to clog the radiator. And of course, less debris in the system means that the chances of engine fires are greatly reduced.

The cooling system also features a reversible fan which automatically activates every 20 minutes, or whenever the operator deems it necessary. To help conserve energy (fuel), the fan spins only as fast as required to keep the engine at the correct operating temperature.

By repositioning the radiator, Caterpillar designers have been able to set the engine lower, thereby providing a reduced centre of gravity. Having that lower centre of gravity has also helped improve front-end stability by up to five percent, and transmission improvements have increased torque by around 14 percent – allowing for faster travel speeds in the same gear.

Design process

So how did all this come about? Well as luck would have it, Caterpillar Inc. had sent out engineering supervisor Dan Stumpo, along with two other company executives to ensure open day attendees had first-hand knowledge immediately available.

As engineering supervisor, Stumpo was in charge of the team that developed the Cat 555D, and has travelled to many locations as part of his role in introducing the new model to the world market.

Speaking to him about design of the machine was quite interesting, and I was intrigued to find out that unlike some other Caterpillar products, which have a large development team, the Cat 555D, design crew consisted of some half-dozen people.

Stumpo said that customer feedback is very important to the design process and this gets taken into account during all stages of a new machine build. Stakeholders which includes, selected forestry operators are also seen as a big part of the finished product, being brought in at strategic points along the way. No doubt their grassroots input is seen by Caterpillar as a key component to longevity of the brand.

The smile on Stumpo’s face is more than a good indication that he is satisfied with the machines that are now rolling off the assembly line. When asked what is next on the drawing board, the smile turns to a cagey look, and after swearing me to secrecy, he hints at a couple of possibilities. The future certainly is looking bright indeed.

Never miss an issue of Deals on Wheels. Subscribe here.

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.