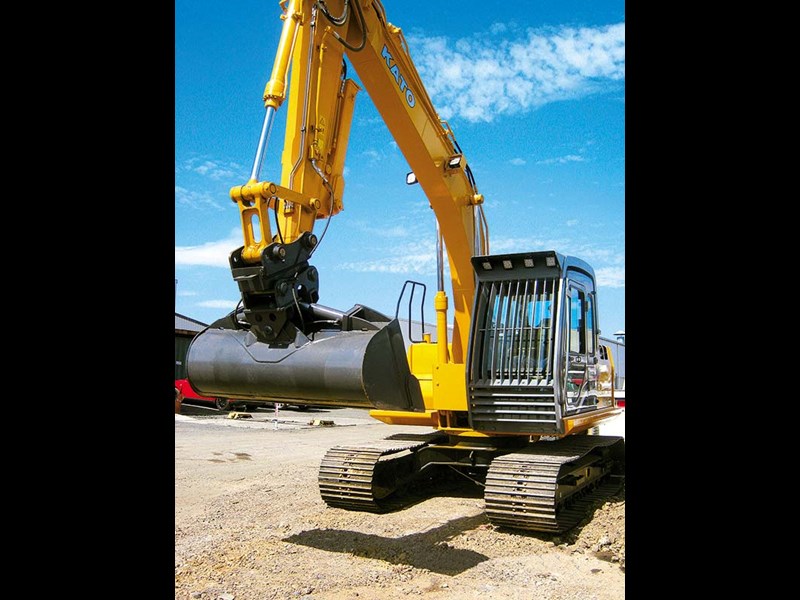

Kato makeover: Kato HD512V add-ons

|

|

|

|

|

|

|

|

|

When Matt Pethybridge bought his new Kato HD512V for his Rotorua-based business a couple of months ago, there were a number of add-ons he asked the machine's suppliers, HPL Distributors Ltd, to arrange to be fitted prior to delivery.

Matt Pethybridge Contracting Ltd does a lot of work for Environment Bay of Plenty, or EBOP as it's more commonly known, so a forestry ROPS cage was a prime requisite.

Also there was the need to have a telescopic hydraulic thumb fitted to operate in conjunction with an extra-wide tilt bucket with a quick hitch.

"Oh and while you're at it," says the machine's new owner. "Could you fit a catwalk to both sides?"

Pethybridge had purchased the new machine just a few weeks shy of Christmas and it was going to have to be put to work as soon as the silly season had morphed into the New Year – he just knew it was going to be a tall order to ask of the supplier.

Jimmy Daisley from the Waikato-based supplier HPL seemed unfazed by the request and promptly got on the phone to Jim Coxhead from BS Engineering Ltd in Auckland.

The two men had a long-term working relationship and his faith in the firm's ability to get the job done was rewarded when just four weeks later, in spite of the Christmas shutdown the completed project was on the transporter and headed for the Bay of Plenty ready for action.

The build

With an extremely tight deadline to work to, on receiving confirmation of the order, the team at BS Engineering sprang into action and ordered the required components not already in stock and immediately set about manufacturing the quick hitch and tilt bucket.

Meanwhile, their in-house design team worked on drawing up the specifications for the purpose-built forestry ROPS cage, of which certain components had to be certified by Cambridge-based registered certifiers, TVL.

While the ROPS cage itself is certified, added certification is required for the posts that secure it to the machine, due to the fact that every brand of digger is configured differently, thus mounting points fix in different positions depending on the excavator it's being attached to.

Fitting the ROPS cage to the Kato HD512V required a bit of modification to the machine's body panels, as was the case when it came to fitting the 100mm-wide catwalks. All work was carried out by the BS Engineering team including spray painting to original specifications.

While all this was taking place, in another part of the workshop the telescopic hydraulic thumb was being manufactured in readiness for fitting-up to the machine.

After a very short break for Christmas pudding, the BS team returned to work and all there was left to do was to fit all the component parts, connect it all up to the auxiliary hydraulics and carry out all pre-delivery checks.

Never miss an issue of Deals on Wheels. Subscribe here.

Keep up to date in the industry by signing up to Deals on Wheels' free newsletter or liking us on Facebook.